Vibro Compaction (VC)

Vibro compaction is a ground improvement technique that can be used to increase the bearing capacity of soil for construction purposes. It involves the use of vibratory hammers to compact the soil, which increases its density and strength. The technique is most commonly used in areas where there is a need for improved foundation support or where there are weak soils that cannot bear heavy loads. Vibro compaction has proven to be an effective and economical way to improve soil conditions and increase bearing capacity, making it an important tool in ground improvement projects.

- A method to stabilize or compact the deep layers of non-cohesive soils

- Suitable to compact loose, granular soils to mitigate liquefaction and reduce settlement, extremely effective in free draining granular soils

- Able to improve the ground up to a depth of 30 meters

- When vibration is applied to such soils, they rearrange themselves under gravitational forces and become denser by reducing the void ratio and compressibility of soil

- This density of soil thus achieved is permanent

- This process can be used in both dry and wet condition of soil

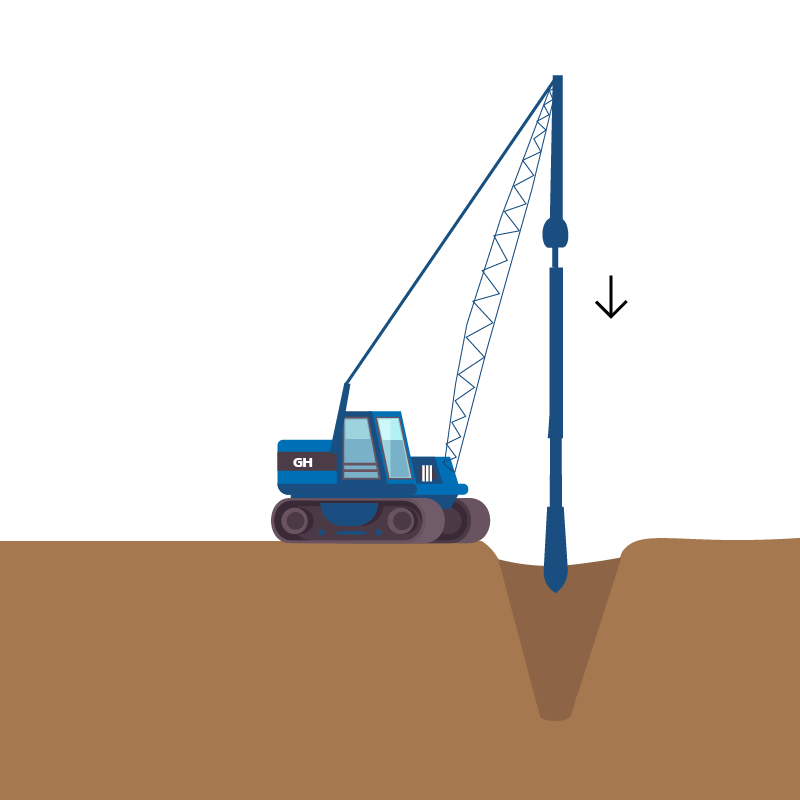

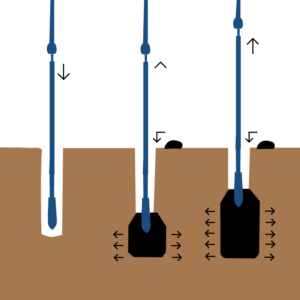

Vibro Compaction Procedure

1. Penetrating by vibrator head and water pressure

2. Compacting and backfilling

3. Repeating up and down until a compacting point is built up to ground level

Vibro Replacement (VR)

Vibro replacement is a ground improvement technique that can be used to enhance the strength and stability of soil. It involves replacing poor soil with stronger material, such as sand or gravel, which provides a more stable foundation for structures built on top of it. Vibro replacement can also reduce settlement and improve drainage. It is an increasingly popular method for improving the quality of soil in areas where traditional methods are not suitable. With vibro replacement, engineers can create a better environment for construction projects, allowing them to build safer and more efficient structures.

- An extension of Vibro Compaction by replace cohesionless soils, after compacting, with large granular column

- Used in soils that do not respond well to vibration alone e.g. stiff soils, soils with more than 15% of fines content

- Constructs dense aggregate columns (stone columns) by means of a downhole vibrator, to reinforce all soils and densify granular soils

Major types of Vibro replacement techniques

- Wet Top Feed : suitable with high water table, silt, etc.

- Dry Bottom Feed : suitable silt and sand below water table